A-B-C Blog

Understanding the Benefits of Using a Pallet Dispenser for Your Warehouse Operations

In today's fast-paced warehouse operations, optimizing efficiency and productivity is paramount. According to a report by the Warehousing Education and Research Council (WERC), 72% of warehouse operations are focused on improving efficiency, while 30% identify manual handling as a key area of waste.

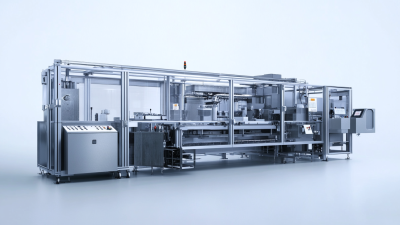

A Pallet Dispenser emerges as a crucial solution in addressing these challenges, automating the pallet handling process and significantly reducing labor costs. By implementing a Pallet Dispenser, facilities can streamline their pallet flow, enhance safety measures, and minimize the risk of workplace injuries—issues that 20% of warehouse managers cite as major concerns.

As the warehousing sector continues to embrace automation, investing in a Pallet Dispenser not only aligns with best practices but also drives operational excellence and supports long-term growth strategies. This article will delve into the various advantages of incorporating a Pallet Dispenser into your warehouse operations, underscoring the vital role it plays in modern supply chain management.

A Pallet Dispenser emerges as a crucial solution in addressing these challenges, automating the pallet handling process and significantly reducing labor costs. By implementing a Pallet Dispenser, facilities can streamline their pallet flow, enhance safety measures, and minimize the risk of workplace injuries—issues that 20% of warehouse managers cite as major concerns.

As the warehousing sector continues to embrace automation, investing in a Pallet Dispenser not only aligns with best practices but also drives operational excellence and supports long-term growth strategies. This article will delve into the various advantages of incorporating a Pallet Dispenser into your warehouse operations, underscoring the vital role it plays in modern supply chain management.

Advantages of Implementing a Pallet Dispenser in Warehouse Operations

Implementing a pallet dispenser in warehouse operations can significantly enhance efficiency and productivity. According to industry research by the Warehousing Education and Research Council (WERC), warehouses that adopt automation technologies, including pallet dispensers, can see efficiency improvements of up to 30%. This device streamlines the process of pallet handling, allowing for quicker access and more organized stack management, reducing the time spent on manual handling.

Tips for successful implementation include ensuring proper training for staff to maximize the effectiveness of the dispenser. Training helps minimize errors and enhances productivity, as employees will be able to use the technology intuitively. Additionally, consider the layout of your warehouse; placing the pallet dispenser in a high-traffic area can further reduce retrieval times, boosting operational flow.

Furthermore, the use of pallet dispensers can lead to a decrease in workplace injuries. The National Safety Council reported that using mechanized solutions for lifting and moving heavy items can reduce the risk of musculoskeletal injuries by up to 50%. This not only enhances employee safety but also results in cost savings by reducing insurance claims and associated downtime.

How a Pallet Dispenser Enhances Efficiency and Safety in Warehousing

In today's fast-paced warehouse environment, the adoption of a pallet dispenser can significantly enhance operational efficiency and safety. By automating the pallet handling process, facilities can reduce the manual labor required, which not only speeds up the workflow but also minimizes the risk of injuries associated with heavy lifting. According to industry reports, companies implementing automated solutions in their warehousing operations have experienced up to a 30% increase in productivity, highlighting the transformative impact such technologies can have.

Moreover, the integration of pallet dispensers contributes to a safer work environment by streamlining inventory management and reducing the chances of accidents. For instance, in remote mining sites where dangerous conditions abound, effective logistics management through automated systems has proven essential for operational safety. Similarly, in feed mill applications, robotic palletizing technologies have shown improved safety metrics and have reduced product damage during handling, further underscoring the safety benefits of these systems within warehousing. With the ongoing growth of e-commerce and logistics demands, the incorporation of such innovative tools becomes indispensable for efficient and safe warehouse operations.

Cost-Effectiveness of Using Pallet Dispensers in Material Handling

Pallet dispensers play a crucial role in enhancing the cost-effectiveness of warehouse operations, particularly in material handling. By automating the process of pallet dispensing, warehouses can significantly reduce labor costs. With traditional methods, workers often need to manually stack and retrieve pallets, which is time-consuming and labor-intensive.

Implementing a pallet dispenser minimizes these manual tasks, allowing employees to focus on more value-added activities, thus optimizing overall productivity.

Pallet dispensers play a crucial role in enhancing the cost-effectiveness of warehouse operations, particularly in material handling. By automating the process of pallet dispensing, warehouses can significantly reduce labor costs. With traditional methods, workers often need to manually stack and retrieve pallets, which is time-consuming and labor-intensive.

Implementing a pallet dispenser minimizes these manual tasks, allowing employees to focus on more value-added activities, thus optimizing overall productivity.

Moreover, pallet dispensers help reduce waste and improve inventory management. They ensure that pallets are organized and readily accessible, leading to less damage and loss of materials. This streamlined approach not only saves money on replacing damaged pallets but also enhances the overall efficiency of the supply chain. In addition, with reduced labor and material costs, businesses can achieve better profit margins, making pallet dispensers an invaluable investment for any warehouse looking to improve its cost-effectiveness in material handling.

Key Features to Look for When Choosing a Pallet Dispenser

When selecting a pallet dispenser for your warehouse operations, it’s essential to understand the key features that can enhance efficiency and productivity. One critical feature is the dispenser's capacity and compatibility with various pallet sizes. According to a report by the Material Handling Industry of America (MHIA), efficient pallet management can improve warehouse throughput by up to 30%. Therefore, investing in a dispenser that accommodates multiple pallet dimensions can significantly optimize space and ensure a smooth workflow.

Another important aspect is ease of operation. Look for a pallet dispenser that incorporates ergonomic design and user-friendly controls. Studies indicate that warehouses with ergonomic equipment report a 25% decrease in worker fatigue, leading to improved performance and reduced injury rates. Additionally, automatic dispensing systems can further streamline processes, driving down labor costs and minimizing loading times.

**Tip:** Always consider the robustness and durability of the dispenser material. Metal units typically offer better longevity and performance than plastic alternatives under heavy use. Also, ensure that the dispenser has adjustable features, which can adapt to changes in your operation or storage needs, providing flexibility as your business evolves.

Understanding the Benefits of Using a Pallet Dispenser for Your Warehouse Operations - Key Features to Look for When Choosing a Pallet Dispenser

| Feature | Description | Benefit |

|---|---|---|

| Automated Pallet Dispensing | Systems that automatically dispense pallets as needed. | Increases efficiency by reducing manual labor and speeds up operations. |

| Durable Construction | Built from robust materials to withstand heavy use. | Enhances longevity and reduces replacement costs. |

| Adjustable Height | Adjustable components to accommodate various pallet sizes. | Provides versatility for different operations and products. |

| Safety Features | Incorporation of safety measures such as emergency stops and guards. | Minimizes risks and promotes a safer working environment. |

| Space Efficiency | Compact designs to maximize floor space in warehouses. | Enables better inventory management and workflow optimization. |

Integrating Pallet Dispensers with Existing Warehouse Technologies

Integrating pallet dispensers with existing warehouse technologies can significantly enhance operational efficiency. By seamlessly connecting these dispensers to inventory management systems, warehouses can automate the tracking of pallet usage, ensuring optimal stock levels are maintained. This integration allows for real-time data exchange, enabling operators to respond quickly to inventory fluctuations and reduce the risk of stockouts.

Moreover, the use of pallet dispensers in conjunction with automated guided vehicles (AGVs) allows for smoother material handling processes. As AGVs transport goods throughout the warehouse, pallet dispensers can provide pallets on demand, eliminating delays associated with manual pallet retrieval. This synergy not only streamlines workflows but also minimizes labor costs and decreases the likelihood of workplace injuries by reducing the need for manual handling of heavy pallets. By prioritizing technology integration, warehouses are poised to achieve greater efficiency and improved safety outcomes.

Related Posts

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Pallet Dispenser for Your Business

-

The Ultimate Guide to Choosing the Right Pallet Dispenser for Your Business Needs

-

2025 Breakthroughs in Industrial Packing Machines: A Comprehensive Guide for Businesses

-

Revolutionizing Your Production Line with Innovative Industrial Packing Machines

-

Exploring the Unique Features and Applications of Various Container and Packaging Solutions

-

The Future of Sustainable Containers and Packaging Innovation